Production Process

Transform Bamboo to Bamboo Scrimber

Step 1: Selection.

We strictly choose high-quality Bamboo ,making sure they are fresh, green-colored, with high fiber content.

Step 2: Splitting.

Fresh bamboo will be cut into standard bamboo tubes and slices using automatic equipment.

Step 3: Slicing.

Bamboo slices will be processed through an automatic flattening machine to remove the green and yellow surfaces.

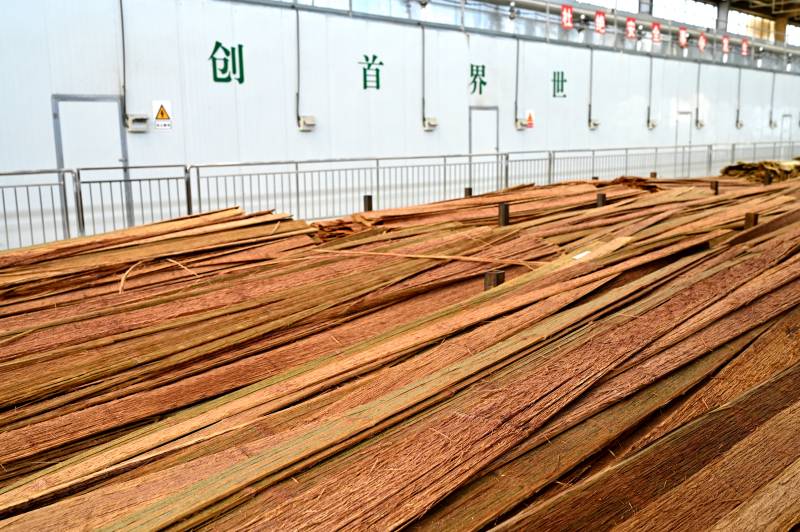

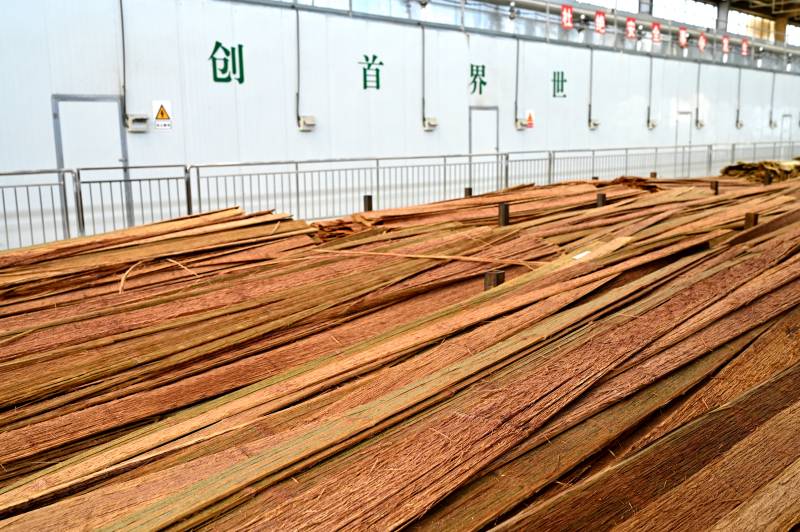

Step 4: Forming Bamboo Bundles.

The bamboo slices retain their original fiber structure and direction, resulting in soft and resilient bamboo bundles.

Step 5: Drying.

We develop a proprietary drying technology that precisely controls the temperature and time of the bamboo bundles, strictly controls their moisture content.

Step 6: Impregnation and Draining.

The dried bamboo bundles undergo impregnation,ensuring uniform adhesive coverage on the bamboo bundles.

Step 7: Secondary Drying and Conditioning.

With precise control of temperature,we will leave the bundles alone 7 to 10 days to achieve more balanced moisture content.

Step 8: Assembly.

Weighting bamboo bundles and assembly them flat ready for compression.

Step 9:Compressing.

Utilizing automated procedures, bamboo panels will be compressed through high temperature and pressure.

Step 10: Quality Inspection.

Our quality department will make sure the compressed bamboo sheets meet the requirements of density, expansion rate, mold resistance, discoloration etc.

The bamboo scrimber sheets will be placed in a temperature and humidity-controlled room for conditioning, and ready for use!